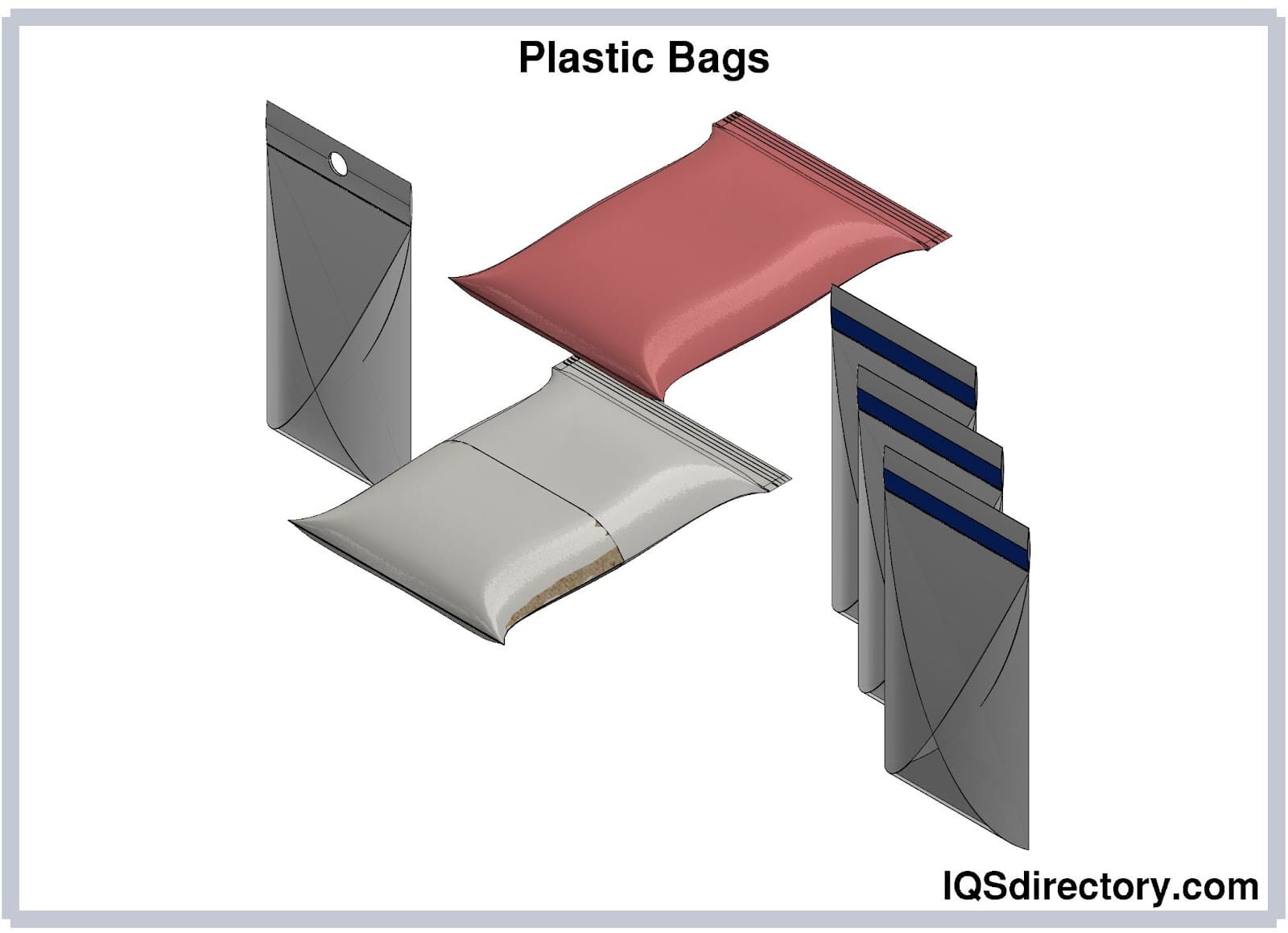

Clear plastic bags are created with low-density polyethylene and polypropylene, which are transparent polymers. Like almost all other plastic bags, these bags’ primary use is to contain and shield goods of all shapes and sizes from the elements, such as dust and moisture. Read More…

Diversified Plastics & Packaging supplies plastic bags for many industries. We deliver prompt service, competitive prices & unparalleled variety in flexible packaging. Fast quotes, free samples when needed, custom made poly bags and stock items of any color and size. Industrial, textile, medical, small & large flexible packaging markets. Visit our website today.

For over 20 years, Universal Plastic Bag has been a leading manufacturer and distributor of plastic bags and packaging supplies. We manufacture gusseted bags, food and fish bags, garment bags, reclosable bags, plastic bags, trash can liners, full color process printing on (poly and poly propylene) bags and sheeting, laminated bag and sheeting, vacuum pouches and standup pouches! Whatever your...

Champion Plastics provides a wide variety of clear plastic bags and films to a broad range of industries. Customization options including levels of opaqueness. We are ISO 9001:2008 certified. Your products deserve packaging that can do its job. Quality, service, and value make up the foundation on which we built our company, and we strive to fulfill those values in providing a wide variety of...

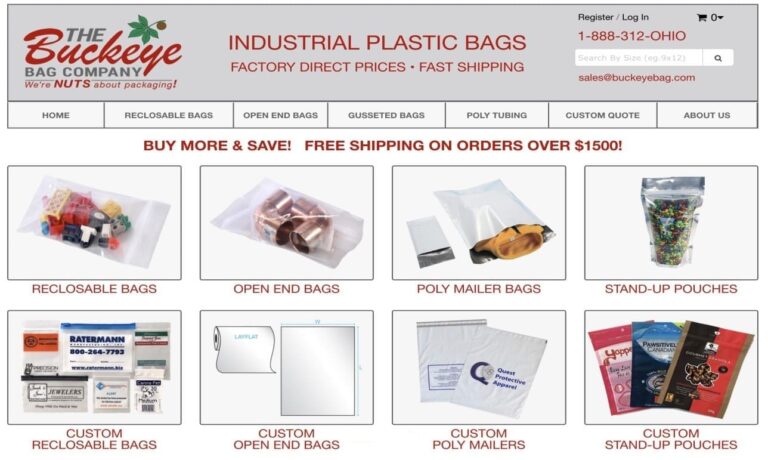

We’re NUTS about plastic bags! Buckeye Bag offers incredibly low prices on a wide selection of commercial quantity industrial plastic bags. Order securely from our online stock product catalog or request a fast, custom quote.

Plastic bags and sheeting custom made for industrial, retail and promotional applications. Materials include LDPE, LLDPE, HDPE, and polypropylene. Custom printing up to 6 colors. Bagbarn.com manufactures products that include bags on rolls, wickets, cut bags, retail bags and more. Promotional bags are available for trade shows & other events as well as environment friendly biodegradable bags.

PolyPro has been a source for custom poly bags and poly products for over 90 years! Your source for custom or unique poly needs made in the USA! Family owned and operated with 90 years in the industry will speak for itself!

Short runs custom print are our specialty - Certificate of Compliance supplied!

ZIPLOCK, BARRIER, POLYETHYLENE, POLYPROPYLENE, SHRINK, LIP/TAPE, CO-EX...

Family-owned for over 75 years, we've been known for our outstanding customer service, a reputation we've earned by always treating customers the way we would like to be treated.

More Clear Plastic Bag Manufacturers

What are Clear Plastic Bags?

These bags, which are acid-free and prevent evaporation and dehydration, extend the shelf life of perishable food and other delicate goods like photographs.

How Clear Plastic Bags are Made

The majority of polythene films are produced using the blown film method. In the Blown Film Extrusion procedure, tiny plastic pellets (called resin) are heated up to a pliable molten state under carefully regulated conditions and then forced (extruded) through a circular die gap to create a continuous tube of plastic.

The tube is cut off at one end while it is still molten, and it is then stretched and inflated to the size and thickness of the desired finished product. Next, it is dragged vertically up a tower to give the inflated plastic bubble time to cool before being flattened and rolled into a roll.

Plastic pellets are fed in at one end of the machine, and film is coiled up at the other. This straightforward method can create films with thicknesses ranging from more than .01 inches (0.254 mm) to as thin as .0004 inches (0.01 mm). Transparent pellets and pellets containing pigment are occasionally combined to create film in various colors.

There should be as little branching as feasible for clear bags to stay transparent rather than just translucent. As an alternative, polypropylene bags are similarly transparent and reasonably priced. Durable clear plastic bags can also be produced using acrylic and polyester resins.

Polyethylene bags are created by heat sealing and cutting rolls of film. Rolls of sheeting or tubing are fed into a device that cuts the material to the right length. The material is then sealed by the machine, which subsequently cuts off a portion of it to create each bag. When using small bags, machine cycle speeds can sometimes create up to 70,000 bags per hour. Other times, big bags might move at 2,000 bags per hour.

Advantages of Clear Plastic Bags

- Customers can see the product via these transparent pouch bags before buying.

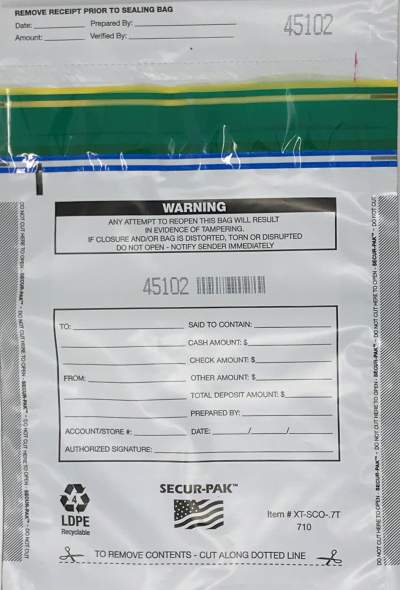

- They come with exceptional barrier qualities.

- They frequently come with robust and puncture-resistant films.

- Several options for clear structures are available, based on the requirements of various shops.

- Despite not always being the most affordable choice, they are quite cost-effective. The bag's thickness and the required number of layers determine the cost.

Disadvantages of Clear Plastic Bags

- Clear plastic bags are ineffective if the intention is to sell a product that is sensitive to light. Light may enter the pouch and interact with the items inside.

- There isn't much room to print the trademark or product information on an entirely transparent body, so marketing possibilities decrease.

- Clear plastic bags are primarily constructed from non-renewable materials. This prompts additional worries and has encouraged the creation of biodegradable plastic bags. These plastic bags are very frail and cannot sit properly, just like cloth and paper. If improperly disposed of, they can cause environmental problems and threaten wildlife, especially if they are ingested or wind up in water bodies. Additionally, improperly disposed-of waste can clog roadside drains, which in the event of severe rains may cause flooding on the roadway.

Applications of Clear Plastic Bags

Clear plastic bags can be seen through thanks to the specific materials used to produce them, increasing product visibility. Translucent plastic bags are frequently used in storage applications, inventory warehouses, or stock rooms because they secure goods while enabling staff or customers to preview available items without opening each package.

Considering the adaptability of the materials used to create clear plastic bags, they can also be utilized as furniture covers, plastic garment dry cleaning bags, ziplock food-grade bags, plastic merchandising bags, and even museum-quality archival baggies. Clear plastic bags are still frequently used in display, marketing, and other applications where visibility is crucial, even though their use is diminishing due to growing environmental concerns over their slow decomposition. Several producers have started producing "biodegradable" clear bags from plant-based materials to make this market more relevant.

Choosing the Proper Clear Plastic Bag Manufacturer

To ensure you have the most productive outcome when purchasing clear plastic bags from a clear plastic bag manufacturer, it is important to compare several companies using our directory of clear plastic bag manufacturers. Each clear plastic bag manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each clear plastic bag business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple clear plastic bag companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services