A poly bag is a widely used resource for shipping and packaging composed of polymer material. It is incredibly strong, flexible, and can be tailored to fit any use. Poly bags are a perfectly manufactured, compact technique for covering and securing goods, parts, and products. Read More…

Diversified Plastics & Packaging supplies plastic bags for many industries. We deliver prompt service, competitive prices & unparalleled variety in flexible packaging. Fast quotes, free samples when needed, custom made poly bags and stock items of any color and size. Industrial, textile, medical, small & large flexible packaging markets. Visit our website today.

For over 20 years, Universal Plastic Bag has been a leading manufacturer and distributor of plastic bags and packaging supplies. We manufacture gusseted bags, food and fish bags, garment bags, reclosable bags, plastic bags, trash can liners, full color process printing on (poly and poly propylene) bags and sheeting, laminated bag and sheeting, vacuum pouches and standup pouches! Whatever your...

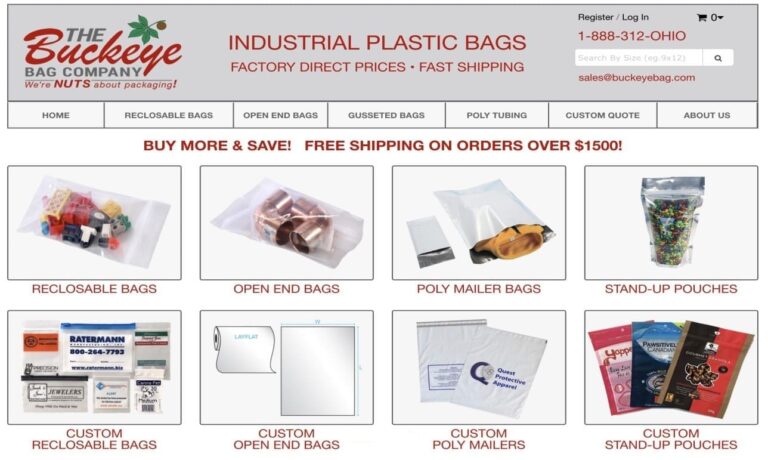

We’re NUTS about plastic bags! Buckeye Bag offers incredibly low prices on a wide selection of commercial quantity industrial plastic bags. Order securely from our online stock product catalog or request a fast, custom quote.

Plastic bags and sheeting custom made for industrial, retail and promotional applications. Materials include LDPE, LLDPE, HDPE, and polypropylene. Custom printing up to 6 colors. Bagbarn.com manufactures products that include bags on rolls, wickets, cut bags, retail bags and more. Promotional bags are available for trade shows & other events as well as environment friendly biodegradable bags.

PolyPro has been a source for custom poly bags and poly products for over 90 years! Your source for custom or unique poly needs made in the USA! Family owned and operated with 90 years in the industry will speak for itself!

Short runs custom print are our specialty - Certificate of Compliance supplied!

ZIPLOCK, BARRIER, POLYETHYLENE, POLYPROPYLENE, SHRINK, LIP/TAPE, CO-EX...

Family-owned for over 75 years, we've been known for our outstanding customer service, a reputation we've earned by always treating customers the way we would like to be treated.

More Poly Bag Manufacturers

These bags are made of polyethylene or polystyrene materials. Although developed during the first industrial revolution, polyethylene wasn't used for poly bags until the 1950s. However, the demand for a cheap, reliable, and practical way to transport items securely and safely has led to the rise in the popularity of poly bags.

How Poly Bags are Made

The strength, weight, and thickness of a poly bag are all influenced by the resin used in its production. Plastic bags are made from five different types of resins: medium-density polyethylene (MDPE), linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), and polypropylene (PP). The main determinants of a bag's durability and strength are its composition and physical attributes. Therefore, choosing the appropriate bag material is the first step in designing and producing high-quality poly bags.

After choosing the resin, it is added to the hopper of an extruder. Plastic pellets were initially melted by simply heating them in a tank or big barrel. However, this caused the material to heat up unevenly, with only the pellets closest to the heat source becoming hotter and more malleable. As a result, the extruder was created, a screw mechanism that heats material at 350 to 450° F (176.6 to 232.2 °C) so that all of the pellets melt evenly. A loading hopper and a die are located at either end of an extruder, which resembles a screw. After being fed into the hopper, the resin is slowly dropped into the extruder's barrel.

Pellets heated by heating units positioned along the length of the barrel migrate along the extruder as the screw rotates. The molten plastic resin emerges from the extruder die in the form of a tube, which is then stretched and expanded to the required size for the poly bag. The plastic tube stays inside the tower until it has been fully expanded and until it has cooled. It looks like a tall vertical plastic balloon in the cooling tower. As it rises, the gas expands, comes into contact with the tower's walls, and cools as it ascends to the cutting rollers.

The tube is fed into the collapsing frame to create the plastic fabric. Then it enters the nip rollers to flatten into a lay-flat state so it can be rolled into a big roll of plastic. Nip rollers increase winding onto a roller, isolate web tension zones, and offer great traction. The inflated film is rolled into a massive roll for processing after it has been flattened and has gone through the collapsing frame and nip rollers. The poly bags will be printed, made, measured, and sealed from these rolls. Each manufacturer has a distinct method for cutting poly bags, which often involves closing the bag.

Along with cutting the bag to length, handles can also be cut and fashioned. Additionally, the cutting operation must accommodate gussets that might have been inserted when the plastic tube was cooling after extrusion.

Applications of Poly Bags

- Food bags: For many years, poly food bags have been available to keep food fresh and high-quality. The many poly food bags protect displayed products from moisture, air, and atmospheric pollutants. One of the numerous designs can be vacuum sealed, removing air from the bag's interior to increase its protective properties. A poly bag must satisfy the Food and Drug Administration's (FDA)'s and the United States Department of Agriculture's (USDA)'s criteria to be designated as a food service or storage bag. On poly bags that have complied with the regulations, there are stamps.

- Trash bags: Poly garbage bags, which come in sizes to accommodate every trash can, from giant bags for yard waste to compact bags for office trash cans, have grown in popularity as a household item. Many garbage management businesses demand that their clients place their non-recyclable rubbish in sturdy trash bags. There are a variety of possible drawstrings, handles, and odor-suppressing trash bags. Therefore, these numerous inventive innovations have substantially improved the trash collecting sector.

Choosing the Proper Poly Bag Manufacturer

To ensure you have the most constructive outcome when purchasing poly bags from a poly bag manufacturer, it is important to compare several companies using our directory of poly bag manufacturers. Each poly bag manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each poly bag business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple poly bag companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

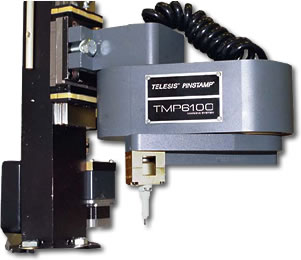

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services