Polyethylene bags are transparent, waterproof containers used in various industrial, commercial, and home situations to preserve, store, or transport items. These poly bags are used regularly by the food, chemical, defense, waste management, retail, medical, construction, and a plethora of other industries. Although polypropylene bags are a popular and more affordable alternative to polyethylene bags, the latter has several advantages that make them more well-liked. Read More…

Diversified Plastics & Packaging supplies plastic bags for many industries. We deliver prompt service, competitive prices & unparalleled variety in flexible packaging. Fast quotes, free samples when needed, custom made poly bags and stock items of any color and size. Industrial, textile, medical, small & large flexible packaging markets. Visit our website today.

For over 20 years, Universal Plastic Bag has been a leading manufacturer and distributor of plastic bags and packaging supplies. We manufacture gusseted bags, food and fish bags, garment bags, reclosable bags, plastic bags, trash can liners, full color process printing on (poly and poly propylene) bags and sheeting, laminated bag and sheeting, vacuum pouches and standup pouches! Whatever your...

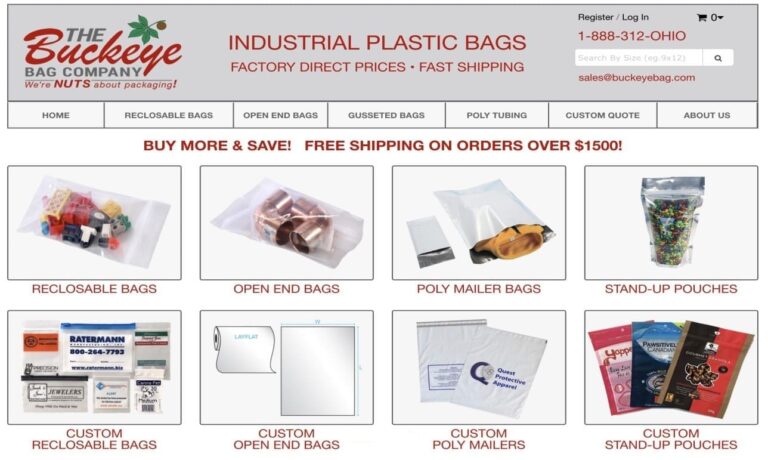

We’re NUTS about plastic bags! Buckeye Bag offers incredibly low prices on a wide selection of commercial quantity industrial plastic bags. Order securely from our online stock product catalog or request a fast, custom quote.

Plastic bags and sheeting custom made for industrial, retail and promotional applications. Materials include LDPE, LLDPE, HDPE, and polypropylene. Custom printing up to 6 colors. Bagbarn.com manufactures products that include bags on rolls, wickets, cut bags, retail bags and more. Promotional bags are available for trade shows & other events as well as environment friendly biodegradable bags.

PolyPro has been a source for custom poly bags and poly products for over 90 years! Your source for custom or unique poly needs made in the USA! Family owned and operated with 90 years in the industry will speak for itself!

Short runs custom print are our specialty - Certificate of Compliance supplied!

ZIPLOCK, BARRIER, POLYETHYLENE, POLYPROPYLENE, SHRINK, LIP/TAPE, CO-EX...

Family-owned for over 75 years, we've been known for our outstanding customer service, a reputation we've earned by always treating customers the way we would like to be treated.

More Polyethylene Bag Manufacturers

Manufacturing Process of Polyethylene Bags

Ethylene, a byproduct of natural gas and petroleum, is the foundational material for polyethylene bags. These plastic resins go through a process called polymerization, which joins a number of monomers to create a polymer or plastic. The thermoplastic produced can belong to any of the numerous polyethylene subcategories. Distinctions between subcategories are created based on molecular weight, branching, or crystallization. The least expensive alternative is high-density polyethylene (HDPE), a non-porous, non-stretching kind that provides the best temperature and moisture resistance. Due to its porous nature, which allows it to stretch, low-density polyethylene (LDPE) is more expensive but provides superior clarity and resistance to ripping.

The new generation metallocene, medium density polyethylene (MDPE), linear low-density polyethylene (LLDPE), ultrahigh molecular weight polyethylene (UHMWPE), and very low-density polyethylene are other forms of polyethylene (VLDPE). Each substance has distinct advantages and disadvantages regarding how plastic bagsare made. Resin beads are heated to between 356 and 464 °F (180 and 240 °C) and then extruded onto a thin film using sheet or blow film techniques to make these bags. Although less common, winding and casting may also be used. The thin, flexible film is flattened by rollers after cooling. Then the bag is cut and sealed into its desired form. Lastly comes finishing touches like painting or adding handles and zippers.

Advantages of Polyethylene Bags

- Due to its many beneficial characteristics, polyethylene can be used in various applications. It is exceedingly ductile and has good impact strength while having low strength and hardness; it will stretch rather than break.

- Compared to other polymers, polyethylene is more durable and resistant to water; therefore, it lasts longer when exposed to the weather.

- Although polyethylene is a good electric insulator and offers resistance to electric trembling, it is susceptible to electrostatic charge. Anti-static substances will stop this.

- The transparency of polyethylene can range from almost clear to opaque, depending on its thickness. Low-density polyethylene (LDPE) is useful for packing because of its clarity.

- It is more economical to recycle polyethylene as HDPE into other products than to manufacture a new product from fresh plastic.

- Low-density polyethylene has a melting point range of 221 to 239 °F (105 to 115 °C), while medium to high-density polyethylene has a melting point range of 248 to 356 °F (120 to 180 °C). It may be used in both high and low temperatures thanks to its excellent heat resistance qualities.

Disadvantages of Polyethylene Bags

- Polyethylene can spend decades in landfills, which are running out of capacity since, like many other plastics, this polymer takes a long time to decompose.

- Incineration is another option for eliminating polyethylene, but this method may emit hazardous gasses.

- The primary sources of polyethylene are petroleum and natural gas, both of which have a finite supply.

- Carbon dioxide emissions, a greenhouse gas that contributes to global warming and climate change, from the production of polyethylene are also high.

- Although most plastic polymers can potentially be recycled, sorting through all of the different varieties is expensive and difficult.

Applications of Polyethylene Bags

- Poly anti-static bags reduce static electricity and guard against electrostatic discharge-related harm (ESD). They are made to hold and protect electronic parts that environmental ESDs could harm. Poly anti-static bags are available in a variety of shapes and sizes and come with fire retardant material, and are airtight for water protection.

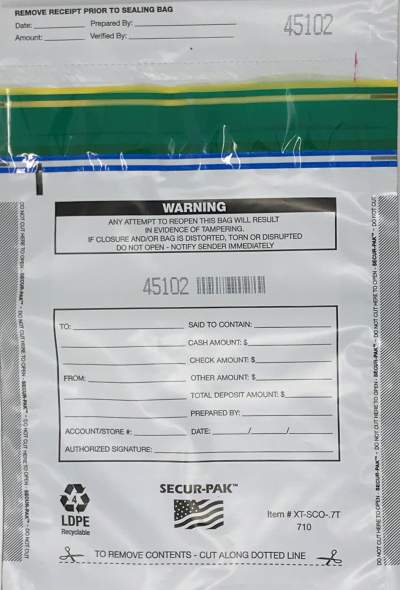

- Products are shipped in mailers or shipping bags to avoid the weight of boxes. Mailer bags come in various styles, such as zip closures, pressure closures, and peel and seal closures. Shipped goods are shielded from weather and environmental toxins by the closure on mailer bags; also, some businesses utilize mailer bags to advertise their brand and display their logo.

- As a result of their sturdiness and longevity, zipper bags are among the most popular bags on the market. They come in various sizes suitable for freezer storage or basic shelf storage. Zipper bags stand out thanks to their tight zip closure, strong solid edges, and reusability. Zipper bags are used in factories and residences as a safe and reliable way to preserve stored products.

Choosing the Right Polyethylene Bag Supplier

To ensure you have the most positive outcome when purchasing polyethylene bags from a polyethylene bag supplier, it is important to compare several companies using our directory of polyethylene bag suppliers. Each polyethylene bag supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each polyethylene bag business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple polyethylene companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

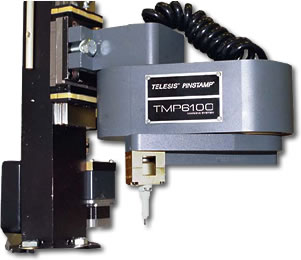

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services