Plastic bags are products utilized in every industrial, commercial and residential context imaginable. With such a wide variety of uses it is no surprise that custom bag creation options are available. Although such an option is not a priority for most residential customers, who can find everything they need at the grocery store or hardware store, some industrial and commercial settings do require specially designed and manufactured plastic bags to suit very specific needs. Because there are so many types of plastic bags, it stands to reason that there are customizing variables for all of them.

Made from polymer resins, which are melted into a liquid state and turned into sheets of film by way of a variety of manufacturing options such as winding, casting, sheet extrusion or blown film extrusion, plastic bags are almost always recyclable. In recent years, biodegradable plastics have also been produced and manufactured. Choosing what type of plastic will be used for a specific plastic bag design is one custom element customers can control. The manufacturing technique also affects the thickness of the film and therefore choosing the method, be it blown film extrusion or sheet extrusion can highly impact the plastic bag outcome.

What the bag will be used for then dictates elements like color, size, print or no print and number of bags produced. If poly bags are being purchased by a manufacturing company packaging items that will be going into stores, then they will want clear plastic bags that are made specially to fit the dimensions of their product and no opening to prevent theft. Medical settings, such as hospitals and doctor’s offices, have very different needs when it comes to plastic bags. Medical plastic bags are needed in a variety of sizes for waste, and patient testing delivery, shipping of vital objects and other reasons as well. Polyethylene bags are common in this field. Regardless of the industry, custom plastic bags are often utilized.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

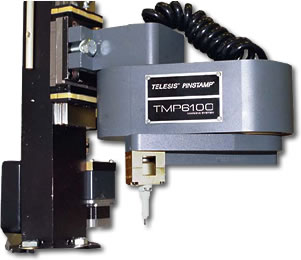

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services